Introduce Roller Thrust Bearing to Emphasis Working of Machinery

Roller Thrust Bearing

You must have heard about friction and the limitations of friction. It’s very necessary to limit the friction otherwise motion could become uneasy.Thrustbearing works on the axial wearing of the shaft. The main function of excel wearing stop preventsthe shaft from drifting and is used to transfer the load which is applied to the shaft.You must be aware that thrust bearings are used in forwarding gears and vehicles, Which reduces noise production.

To support radial load roller bearings are used in the shafts. RollerThrust bearing also minimises the effect of temperature and additional load on the machine functioning. Roller bearing are a kind of rolling element that consider some rollers in place of balls that are used in ball bearings. Some cylindrical-shaped bearings are used as cylindrical shapesto help in handling greater radial loads.Roller bearings have a capacity of handling heavier loads as compared to the ball bearing.

Three types of rollers thrust bearing

Roller bearingsare basically of three types that are highly used in industrial applications. These are used in pulp and paper processing equipment and are used in gearboxes in vehicles.

The spherical thrust roller bearing:this kind of bearing isdesigned in asymmetrical roller which accommodates axial loads acting in a single direction. These are highly used for lubrication. Design of roller thrust bearing is designed in such a way that it creates a pumping action which anti-war a flow from smaller to larger roller complexion.

Tapered thrust wearing: this kind of thrust bearing use tapered rollers. This may have single or double type bearings. Double type bearings are preferred for axial load supports in a rolling mill.

The cylindrical roller thrust bearing: this kind of rollers have single row, double row and three-row types 4 inhibiting dams with heavy load capabilities. These are widely used to support axial heavy loads as these are built with high-quality axial rigidity.

Needle roller bearing, Needle roller bearings are composed of pressed steel plates for runway washers. These are built with high load-bearing capabilities and pause is the smallest cross-sectional area teaser of immense use for the accurate functioning of a machine.

The Roller thrust bearingsuse cylindrical rollers and consist of single rows, two rows and the three-rowsystem. These have high axial rigidity and are preferred to handle heavy axial loads. There are some specific areas where roller thrust bearings are highly recommended such as in engines, agricultural industries and aviation cargo systems and medical equipment, powerhouse and heavy machinery.

So, use the quality bearing and increase the functioning efficiency and life span of machinery.

What Are The Benefits Gained By Implementing 27001 Compliance?

27001 Compliance

The organization needs to acquire different certifications for gaining compliance from the regulatory authorities. Gaining various compliances is essential as it helps the organization to gain a reputation for their business. This ensures the customers that they are using the products and services of the organization that takes care of their customer’s data security.

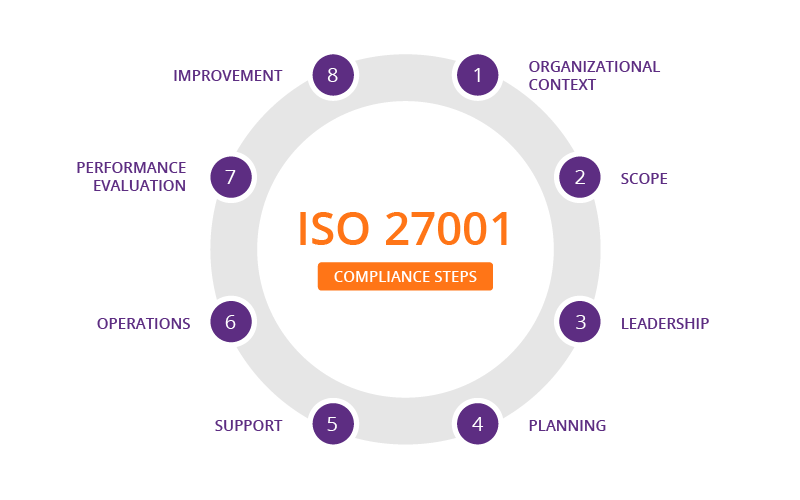

Importance of having 27001 compliances:

The 27001-compliance certificate is important for demonstrating that the organization has concerns and has invested in protecting the people, processes, systems, techniques, and try their best to protect their sensitive data. This compliance helps the organization to monitor, review, maintain and improve the organization’s information system management system. Fulfilling the requirements reduces the chances of data breaches.

Benefits of 27001 compliance:

The different benefits gained by the organization on completing the 27001 compliance include:

Build competitive edge: Compliance certification allows the organization to demonstrate that they follow good security practices and improves the relationship with their customers. The compliance helps to retain the existing customers along with gaining new ones thus moving ahead in this competitive world.

Avoid penalties: Non-compliance increases the chances of data theft and security breaches. In case of breaches, the organization has to bear heavy fines and penalties. Having this compliance certificate ensures that the organization has reduced the chances of a breach and thus avoids heavy penalties.

Build reputation: Gaining compliance reduces the chances of cyberattacks. Implementing compliance helps the organization in protecting themselves against security threats and thus protecting their business and building their reputation.

Reduced frequency of audits: The 27001 compliance certification is globally accepted and indicates that the organization has effective security features. This negates the need for performing frequent audits.

Regulatory requirements: The standards designed for compliance ensure the selection of adequate security controls for protecting the information. This helps the organization to comply with the legal, business, contractual, regulatory requirements.

Understanding the different benefits gained by the 27001 compliance, the organization should get the compliance certificate to enhance and secure their business.

Why is PCI DSS compliance required?

PCI DSS compliance

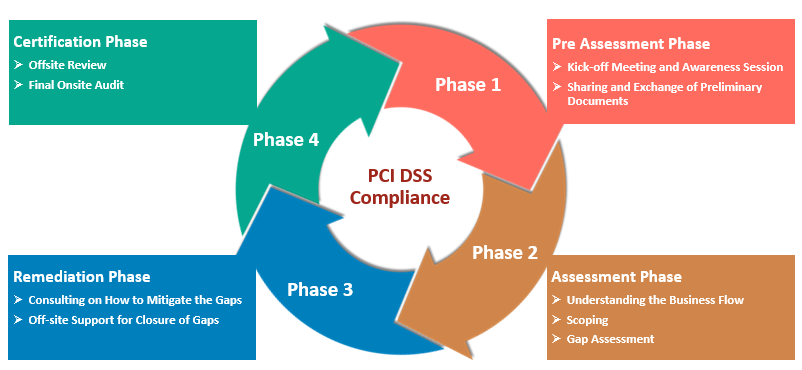

Payment Card Industry Data Security Standard is called PCI DSS. It provided the information for the technical and the operational requirements for protecting the account data. It applies to all those who store, process or transmit cardholder data and payment authentication data.

There is an increase in the electronic payment systems and this also led to an increase in cyber crimes. If the PCI DSS compliance is not followed then there are changes of security breach. A security incident may damage the brand’s reputation. There may be loss of customers and drop in revenue. It may lead to legal actions too.

Benefits of PCI DSS

The many benefits of PCI DSS are as follows:

The PCI DSS ensures that the system is secure and this helps to develop the trust of the customers.

It reduces the risk of cyber crimes and makes cardholder data and cardholder data environments safe.

Being PCI compliance will help the businesses to grow and they can promote themselves as secure businesses.

The business can promote themselves as committed to protecting the customer data by following PCI DSS.

Following PCI DSS will prepare the businesses better with the other regulations standards like ISMS and more.

If PCI DSS is implemented successfully then it will lead to an overall improvement in the IT infrastructure.

Requirements for PCI DSS

The following are the PCI DSS compliance requirements:

You should install and maintain a secure firewall to restrict the incoming traffic. You should follow a strict password usage policy.

The stored customer data should be protected and you should encrypt the customer data across networks.

You should install and maintain anti-virus software and do the necessary updates on the devices that manage cardholder data.

You should control the access to the cardholder data and unless specified the data should not be available to any person.

You should avoid physical access to data and use authentication policies for accessing system data.

All the activities regarding the cardholder data must be maintained in a log and you should regularly test the cardholder data systems for vulnerabilities.

You should maintain an information security policy for all personnel.

Sikh Wedding Invitation Cards: Trends And Features In Cards!

Sikh Wedding Invitation Cards | images. lh3.googleusercontent.com

Sikhs like to get wedding invites matching their tastes and preferences. Their weddings are known as “Anand Karaj” ceremonies and the wedding card is known as the “Anand Karaj” cards. Sikh weddings are performed in the gurdwara under the guidance of the priest and the couple take four vows. The holy book of the Sikhs has extolled the marriage and by marriage the atma is merging with the parmatma. Sikhs love to spend lavishly on celebrations and their weddings and wedding cards are grand.

The Speciality Of Sikh Wedding Invitation Cards

When you browse the sites of online wedding invites you will come across a great variety of Sikh wedding cards. You will notice that Sikh wedding invitation cards are available in a great variety and varied price ranges. When you go through the samples you will come across expensive premium cards and other cards. Hosts desire to spend lavishly on the wedding card and new trends are accepted gladly.

You will find Onkar and Kandha used in the Sikh wedding invites. At least a religious symbol is seen in both modern and traditional card. You will also see verses from the holy scriptures used in the wedding invites and these extol the beauty of sharing and caring for one another after marriage. The scriptures have repeatedly pointed out that two equal partners are taking vows and have decided to be the man and lady henceforth.

Designs In Sikh Marriage Card Invitations

You will find initial designs, bride and groom in wedding costumes, floral designs, jewellery designs, rangoli designs, geometric designs, symmetric designs,etc. You can also include your paintings in your cards. If you are creative, you can create your designs and get them printed in Sikh marriage card invitations with the help of card designers. You will find the photographs of the bride and groom in some cards. 3 D floral designs are used in the cards and the placement of the designs are also very appealing.

Colour Preferences!

You will come across a range of colours in Sikh wedding invites and apart from the regular blue, green, mustard and pastels you will find grey and dark orange and other colours chosen by hosts. Golden colour cards are trending and you will find the preference for metallic colours higher in the community.

Materials Used!

Today the preference for eco friendly cards is high as it supports a good cause. High quality textured paper, handmade paper and high-quality GSM paper are used for the cards. Colourful and vibrant cards are preferred and they are ready to spend on embellishments, semi-precious stones, satin ribbons and bows.

Understanding The Importance and Advantages of Ball Bearing Rollers

Ball Bearing Rollers

Bearings are the smallest elements of the machine that are responsible for making various motions possible without friction. The different motions are possible in the machine due to these bearings that include circular, linear, etc. The different variations in the rolling elements include balls, spheres, cylinders, tapered cylinders, needles, etc.

Variants of ball bearing rollers:

There are different types of rolling elements available but the most common and the basic rolling element is the ball roller. These are different types of bearings that incorporate these balls as the rolling elements and these include:

Deep-groove bearings: These are the commonly used bearings that have the inner and the outer raceways having a circular arc that accommodate these balls. These bearings can accommodate the axial as well as radial loads in both directions. As these bearings have low torque, they attain higher seed with very little power loss.

Magneto bearings: The inner raceways are shallower as compared to the outer ones so these two can be separated. This helps in the easy mounting of the bearings.

Single-row angular contact bearing: The ball bearings in these make a specific angle of contact that varies from 15, 25, 30, and 45. Higher the contact angle, higher load-carrying capacity is attained. For high speed of motion, a smaller contact angle is preferred. For increasing the efficiency of these bearings, they are used in pairs.

Duplex angular bearings: In these bearings, the single-row bearings are used in pairs. The arrangement of these rows while coupling defines the different types of bearings like back-to-back (DB type), face-to-face (DF types), and tandem (DT type).DF and DT variants are useful while handling the axial and radial loads in either direction. DT type of bearings is preferred when handling heavy loads in a single direction.

Four-point contact bearing: The inner raceway has a slit in its radial plate that helps in separating the outer and the inner ring. The contact angle in these bearings is 35 degrees and it holds the axial load in either direction.

Thrust bearing: The ball holding rings are washer-like. These bearings may include 2 or more rings. These modifications help in accommodating the loads in a single or double direction.

Self-aligning bearing: The inner ring incorporated 2 raceways as compared to only one raceway in the outer ring. This setting allows to automatically correcting the errors that arise due to minor misalignment between the shaft and housing.

Considering the simplicity and the various advantages of using these ball bearing rollers, these are the most convenient choice of bearings. Selection of the proper type of bearing is important for its efficient working.

Know The Structure and materials used in The Pillow Block Bearing

Bearing Pillow Block | images.wedmegood.com

Bearings are the most important elements in machineries that provide smooth functioning of machinery. For this reason, bearing material is used in such a way that in any condition, theyare strong enough to bear the radial as well as axial loads. The bearing housing protects the bearings from a lot of difficulties and is manufactured in as strong as a possible way to have a better quality of the product. Well, the bearing pillow block housings are made up of several products which are considered by keeping in mind all the factors with different properties.

The Structure of bearing pillow block

The pillow block bearing provides support to a rotating shaft and assists in the rotation of any heavy load or object. This bearing pillow block consists of two parts. The outer housing part needs to be attached or fixed to the object that one must rotate. This housing part has holes or slots that assist in mounting it to the surface and adjusting. The second part of the pillow block bearing is the bearing that holds the shaft of the object or a machine that allows rotational movement.

The material used in the manufacturing of the bearings.

The material used is just chosen by looking after all the factors affecting the product. Well,aluminum has a high load carrying capacity. Other than this the aluminum has some other characteristics which make it suitable to be used as a manufacturing element and those characteristics are its fatigue strength and thermal conductivity.

Plastic fiber is a general material which is used widely in the world. It consists of some other characteristics which make it useful as, it is tough, highlyresistant,and alsohasa great pressure rating with it.

Acetyl polymers areactually existsemi-crystalline form. These have a high chemical resistance, fatigue resistance and lubricity with it.These properties make it more useful to be used in the manufacture of the bearings.

Cast iron is another option to go for.other than iron it also consists of a small amount of carbon and silicon. This material is naturally composite and consists of two phases such as the stable and the metastable phases during its treatment which includes heating. Well, its carbon part consists of two chemical and morphological forms, and these are also dispersible.

Pressed steel is also taken into consideration as it has been pressed rather than being machined and it is a low carbon steel.These are less expensive as compared to other elements used and are considered for the matters which have a lower axial load. This is generally used to manufacture the bearing pillow block. Well, it is corrosion free and highly resistant to be used.

Angular Contact ball Bearing for Better Performance and Load Capacity

Angular Contact Ball Bearing

There are different kinds of bearings available for different purposes. One of the kinds is spherical plain bearing, which comes with several features and characteristics. These bearings come in sizes and they include metric and inches.

The spherical bearings are of high quality and they could be used in vehicles (high-way vehicles such as trucks and tankers), equipment that work on high power and have good load capacity such as agricultural equipment and mining and construction equipment. The spherical bearings could also be used in industries such as manufacturing, textile, and industrial units.

Angular contact ball bearings

There is another type of bearing called as the angular contact ball bearing. This kind of bearing combines cast-iron, ball bearing and seal. The spherical internal surface of housing enables it to self-alignment, which helps as the fitting would be adjusted automatically. The sizes come in mm and inches and the type used depends upon the equipment that is being used.

Now, there are different designs available for angular ball bearings too. The double row angular bearings have two balls on either side, which helps for a smooth ride. It takes up less axial space and helps in balance while tilting. It, too, can accommodate radial and axial loads. Single row angular ball bearing, is strong and therefore, can accommodate high loads. With this kind of ball bearing, it is possible to change between speeds i.e., accelerate and deaccelerate without worry.

Four-point contact bearing (ball) can support axial load. They have bearings that can be separated from the cage assembly. The important feature is that it helps in ease of lubrication since there is good way of oil flowing between parts.

Depending upon the warranty and the type of bearings that is used, these have after sales warranty. Some need regular maintenance while some can run without regular maintenance with regular check on the working.

The types of Angular Contact bearing include:

Sigle Row: These are resistant to wear and tear and are available with steel and steel, steel and bronze, steel on composite material and fabric.

Double row: Double-row ball bearings enables the equipment to run at high speed with low friction but with cooler temperatures.

Multiple row: These are used in equipment or things that have a very large amount of misalignment. It can take high capacity and has lowest amount of friction.

When it comes to angular contact ball bearings, it has a bigger and higher use. The main features are that it has an inner and outer ring. These face the bearing axis. This helps in taking up combined loads, both axial and radial loads.